- View Mobile Number

honeybansal429@gmail.com

Manufacturing

RAW MATERIAL

- The key ingredient in the manufacturing of quality PVC-U pipes is the basic raw material-PVC resin.

- Suspension grade PVC is used in the compounds from which PVC-U pipes are made.

- Some of the important features of suspension grade PVC are:

- Excellent thermal stability - which ensures high output rates with better finished products.

- Uniformity - in terms of practice size and molecular weight distribution.

- Low ‘Fish-eye’ and ‘Dark Resin’ cont.

- Low VCM content

- Low volatile content.

PVC COMPOUN DS

The basic raw material is PVC. Other ingredients are stabilizers, lubricants, fillers, pigments etc.

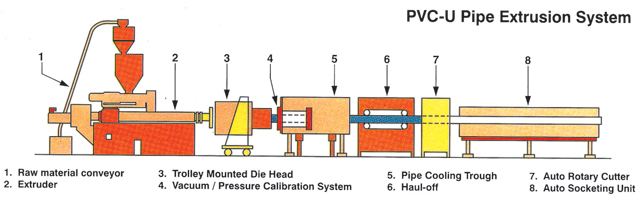

EXTRUSION

PVC compound is extruded into PVC-U pipes using the latest sophisticated equipment. Automatic in-line machines complete the fully automatic process by cutting the pipe into standard lengths and stacking them to prevent warping.

RIGID PVC FITTINGS

- The process for the manufacture of rigid PVC fittings is similar to that for the manufacture of PVC pipes. The only difference is that after the PVC resin is compounded, the material is enjection moulded through modern automatic screw type injection moulding machines. It then ‘flows’ into specially designed moulds, which have high locking pressures ranging in hundreds of tons, and where specified temperatures are accurately attained. This is followed by a cooling process for a predetermined time after which the pipe fitting is ejected, and made ready for testing.

- Fittings are also manufactured by fabrication from PVC-U pipes. Ravindra fittings can be used with excessive loads without the least chance of rupture or failure despite the load on the pipe.